Gelcasting Molding

Gelcasting, a ceramic forming process, was developed in the early 1990s at Oak Ridge National Laboratory by Prof. M. A. Janney. His method uses a mixture of organic monomers dissolved in solvents in which metals are suspended to form a low viscosity slurry (a concentrated suspension) which is then injected into a mold. This allows us to produce magnetic blocks with complex shapes. As this process has advanced from the laboratory to mass production, it has attracted interest from industrial customers thanks to its simplicity.

Our molds are able to use Gelcasting methods to form neodymium magnets. First, ferric neodymium powders must be suspended in an organic mixture to form a slurry which can then be injected into our molds. During magnetization, monomers within the slurry undergo polymerization forming a lattice structure with aligned magnetic regions (poles). Once this gel has been sintered, the lattice forms into a dense magnetic block.

To compress the gel in the mold, the press uses punches that must move simultaneously in a fixed direction but at different speeds with respect to the mold’s cavity. This process is controlled by software to achieve the optimal compression required for the desired uniformity. The gel’s density at the top, middle and bottom of the mold must of course remain constant.

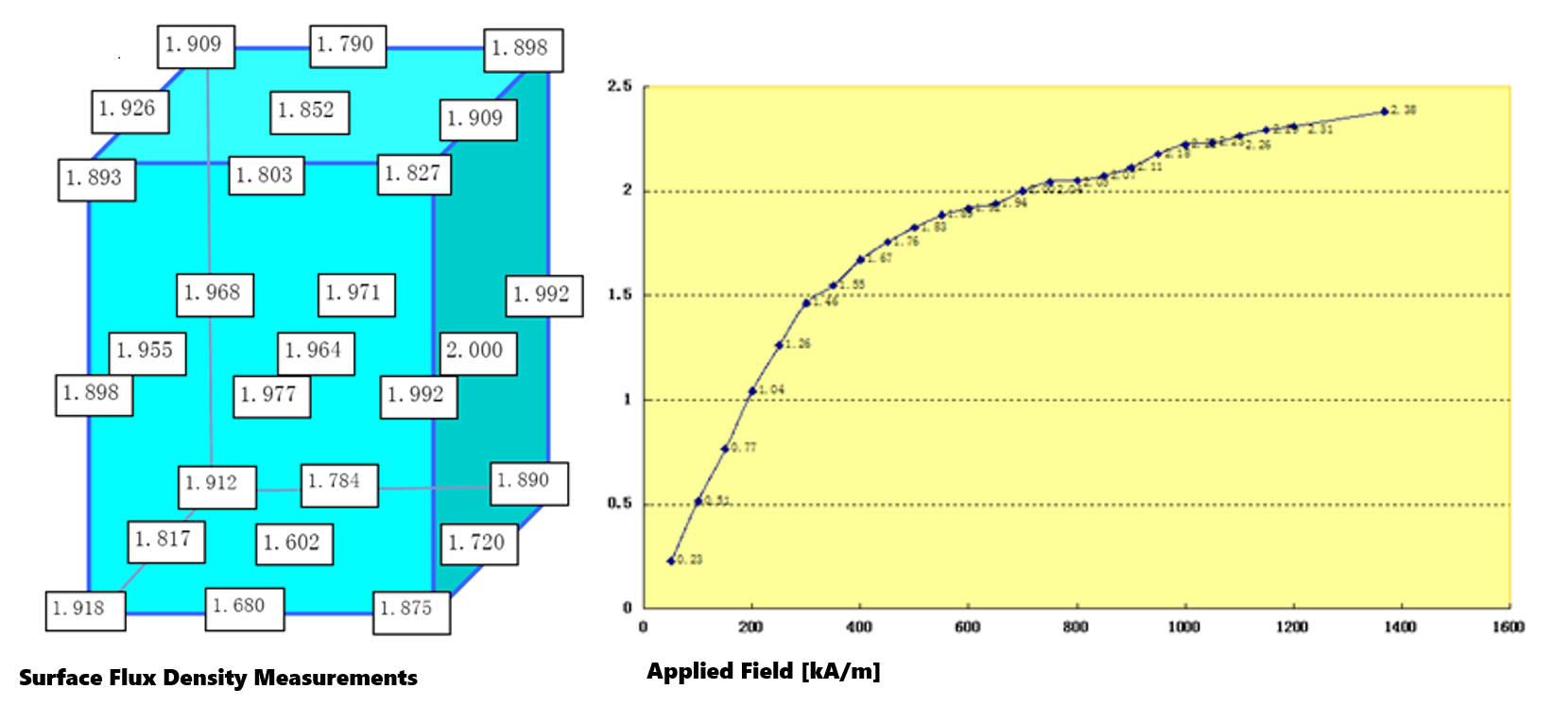

Free-floating compression ensures that we obtain consistent quality when producing neodymium magnets. Examples of the resultant blocks form by this method are shown in the photos.

We have also improved the uniformity of the external alignment field that must be applied to the Gelcasting slurries. Our current technologies allow us to maintain field strengths up to 2.3 Tesla within the molds. At these levels we can guarantee stable internal fields even under continuous operational conditions.